Thus, this review focuses on the simulation modeling of the PCB assembly within a reflow oven using different numerical approaches. The simulation tools have recently facilitated the Cu pillar bump research during the PCB assembly process. The conversion of the flip-chip interconnection bump from the solder ball to the Cu pillar bump with the solder cap and the joint performance within the reflow oven are presented in this review.

This technology with area array feature is a surface mount technology process used to form interconnection bonding between ball grid array chip and printed circuit board (PCB) by the reflow soldering process. This paper reviewed the state-of-art copper pillar technology in flip-chip packaging, driven by the semiconductor industry’s demands for thinner and faster data transmission. The results are useful for studying further improvements to achieve temperature uniformity within the oven chamber. The rotational fan generates an unsteady flow that induces inhomogeneous temperature at different positions in the reflow oven cavity. An in-depth study using the simulation approach reveals that the temperature distribution of the desktop reflow oven is dependent on several factors, namely fan speed, FPCB position, and FPCB thickness. The FPCB surface also has a higher surface temperature than oven air during the operating reflow profile. It was found that the temperature distribution was inhomogeneous along with the phases. The simulation of the model has a great consensus between the experimental data.

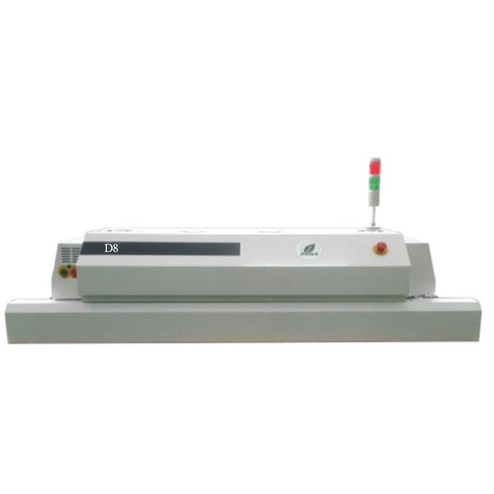

The experimental work acts as a benchmark and the reflow profile was set to follow the standards of JSTD-020E. Since the radiation effect is dominant in the reflow process, a discrete ordinate (DO) model was selected to simulate the effect. A computer-based model that imitates a real-time oven was developed with practical boundary conditions. This paper presents the study of infrared (IR) reflow oven characteristics for suitable operating conditions of the flexible printed circuit board (FPCB) in the reflow soldering process.

0 kommentar(er)

0 kommentar(er)